Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Description:In the previous section, we have already introduced what WPC is and its pros and cons. Today, we will discuss co-extrusion WPC.

Definition of co-extrusion WPC panel

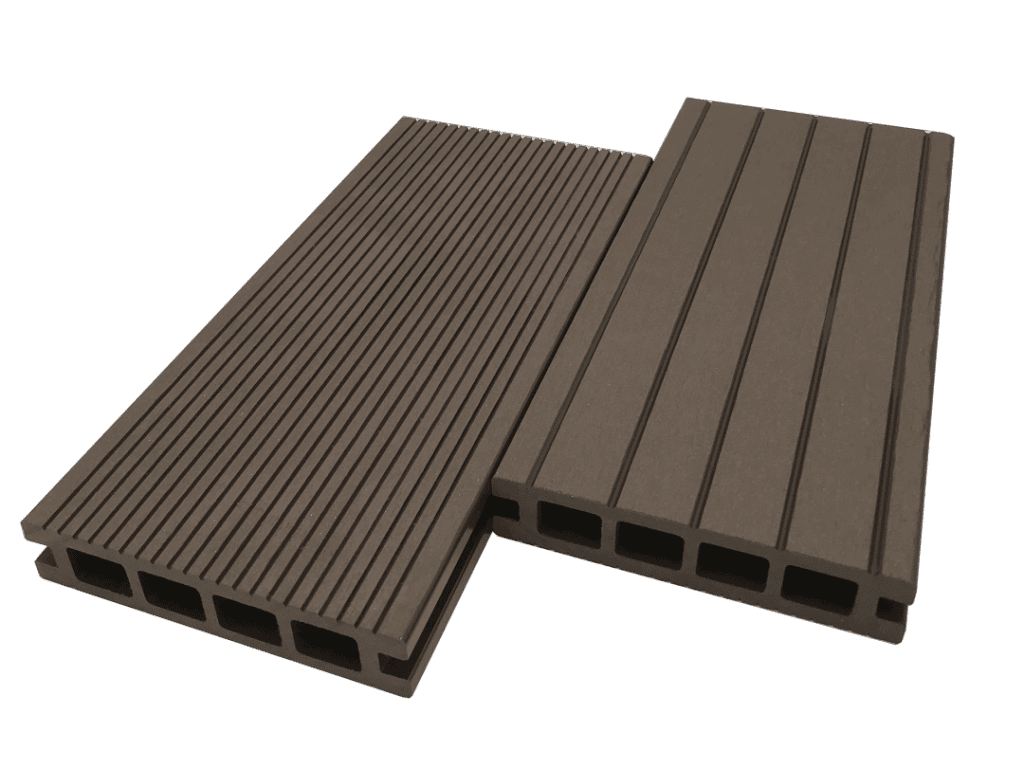

With the development of WPC technology, a new generation of improved WPC materials has emerged, co-extrusion WPC.The co-extrusion WPC has a high-performance shield layer on the surface, with a thickness of 0.5mm or 0.8mm. The interior of the co-extrusion WPC consists of wood powder, plastic, and additives.

Understanding the Co-Extrusion WPC Process

The “Co-Extrusion” process involves the extrusion of many layers of material, including a durable outer layer that provides protection against stains, fading, and scratches, and a core layer that provides strength and stability.

Once the wood is dried and mixed with the polymer, the extrusion process can occur. The mixture is fed into the barrel of the machine and pushed through the die. Once formed, the profile is extruded from the machine and cooled.

Key Features of Co-Extrusion WPC Panels

Durability and weather resistance

Compared to traditional WPC, co-extrusion WPC offers superior durability and weather resistance. If you have more stringent quality requirements, we recommend choosing Aludream’s co-extrusion WPC panel.

Enhanced strength and structural integrity

Co-extrusion WPC not only offers increased durability and weather resistance but also enhances strength and structural integrity. The addition of the high-performance shield layer provides an extra protective barrier, making the panels more resistant to impact, bending, and warping. The combination of wood powder, plastic, and additives in the interior composition further reinforces the strength of the co-extrusion WPC. This enhanced strength and structural integrity make co-extrusion WPC an ideal choice for various applications requiring robust and long-lasting materials, such as decking, railing, fencing, and other outdoor structures.

Variety of design options and aesthetics

Additionally, co-extrusion WPC panels can be manufactured with different surface finishes, such as embossed or brushed textures, further enhancing the visual appeal and adding depth to the design. The panels can also be produced in different sizes and shapes to suit specific project requirements.

Furthermore, co-extrusion WPC allows for easy integration of extra features, such as hidden fastening systems or decorative accents, which contribute to the aesthetic appeal of the panels.

Whether you are looking for a natural wood look, a modern sleek appearance, or something unique, co-extrusion WPC provides ample design options to meet your aesthetic preferences and complement any architectural style.

Low maintenance requirements

The protective layer applied during co-extrusion provides several benefits that contribute to the low maintenance nature of WPC, it enhances the durability and resistance of the material, making it more resilient to external factors such as weathering, UV radiation, and moisture. As a result, it requires less frequent repairs or replacements compared to traditional wood.

The outer layer acts as a barrier, preventing stains, dirt, and other contaminants from penetrating the surface. This makes cleaning easy, requiring only mild soap and water. Unlike wood, WPC does not require regular painting, staining, or sealing to maintain its appearance and functionality.

Thank you for your reading! You have a clear understanding of what co-extrusion WPC is and how it is formed. If you would like to learn more about WPC materials, please click here:News

Please feel free to get in touch with us anytime. Aludream is here to assist you in using WPC for your projects.